Most industrial types of equipment are inductive loads hence, they required two kinds of power been consumed by them (kW - to perform the actual work and kVAR - reactive power to sustain the magnetic field of the load).

Example of inductive load - Electric motors, Induction furnaces, Lighting ballasts, etc basically loads with the composition of coils for their design.

While kW is the useful power required to keep the machine running. The kVAR basically does not perform any useful work except to help to sustain the magnetic field in the equipment.

For example - if you had an electric motor that was operating at 100kW and the apparent power was 125kVA. Hence, power factor will be 0.8 (kW/kVA = 100/125 = 0.8pf). This means kVA decreases if pf increases.

As an example -

A 100kW load operating at 142kVA will have 0.7pf (70% efficient) and at 105kVA the pf will be 0.95(95%). This means the more you correct your pf the lesser the kVA that will be consumed and the lesser the utility you are going to pay.

One common method of improving the power factor is connecting capacitors in parallel to the load.

When apparent power (kVA) is greater than working power (kW), the utility must supply the excess reactive current plus the working current. Power capacitors act as reactive current generators.

By providing the reactive current, they reduce the total amount of current your system must draw from the utility

What do I save by Installing Capacitor Bank

- Reduced electric utility bill

- Reduce system maintenance

- Increase life span of an equipment

- Reduce losses

- Improve voltage

How much can I save by Installing Capacitor Banks

Scenario 1 (kVA billing) -

Assume an uncorrected 460kVA demand, 480V, three-phase at 0.87 power factor (normally good)

Billing:

$4.75/kVA demand

Correct to 0.97 power factor

Solution:

kVA x power factor = kW

460 x 0.87 = 400kW actual demand

kW/PF = kVA

400/0.97 = 412 corrected billing demand

From below table (Table 6) kW multipliers, to raise the power factor from 0.87 to 0.97 requires capacitor:

Multiplier of 0.316 x kW

0.316 x 400 = 126kVAR (use 140kVAR)

Uncorrected original billing:

460kVA x $4.75 = ($2185 / month) - ($1957) = $228/month savings = $228 x 12 = $2,736 annual savings

Corrected new billing:

412kVA x $4.75 = $1957/month

140kVAR, 480V capacitor cost $1600 (installation extra)

This capacitor pays for itself in less than eight month

Kilowatt Demand Billing with Power Factor Adjustment

The utility charges according to the kW demand and adds a surcharge or adjustment for power factor. The adjustment may be a multiplier applied to kW demand. The following formula shows a billing based on a 90% power factor:

kW demand x 0.9 (divided by ) actual power factor

If a power factor was 0.84, the utility would require 7% increase in billing as shown below:

kW x 0.90 (divided by) 0.84 = 107 (multiplier)

Some utilities charge for low power factor but give credit or bonus for power above a certain level.

Scenario 1:

Assume a 400kW load, 87% power factor with the following utility tariff

Demand charges:

First 40kW @ $10.00/kW monthly billing demand

Next 160kW @ $9.50/kW

Next 800kW @ $9.00/kW

All over 1000kW @ $8.50/kW

Power factor clause:

Rates are based on a power factor of 90% or higher. When the power factor

is less than 85%, the demand will be increased 1% for each 1%

that the power factor is below 90%. If the power factor is higher

than 95%, the demand will be decreased 1% for each 1% that the

power factor is above 90%.

There would be no penalty for 87% power factor. However, a

bonus could be credited if the power factor were raised to 96%.

To raise an 87% power factor to 96%, refer to Table 6.

Find 0.275 x 400 kW = 110 kVAR. (Select 120 kVAR to ensure the

maintenance of the 96% level.)

To calculate savings:

Normal 400 kW billing demand

First 40 kW @ $10.00 = $ 400.00

Next 160 kW @ $ 9.50 = $1520.00

Bal. 200 kW @ $ 9.00 = $1800.00

Total(addition of normal+first+next) 400 kW $3720.00 normal monthly billing

New billing:

kW x 0.90 (divided by) New power factor = 400 x 0.90 (divided by) 0.96 = 375kW demand

First 40 kW @ $10.00 = $ 400.00

Next 160 kW @ $ 9.50 = $1520.00

Bal. 175 kW @ $ 9.00 = $1575.00

$3495.00 power factor adjusted billing

Further instruction for Table 6:1. Find the present power factor in column one2. Read across to optimum power factor column3. Multiply that number by kW demand

Example:If your plant consumes 410 kW, is currently operating at 73% power

factor, and you want to correct power factor to 95%, you would: 1. Find 0.73 in column one2. Read across to 0.95 column3. Multiply 0.607 by 410 = 2494. You need 250kVAR to bring your plant to 95% power factor

If you don’t know the existing power factor level of your plant,

you will have to calculate it before using Table 6 on the

following page. To calculate existing power factor: kW divided by

kVA = power factor.

How can I select the right capacitors for my specific application needs?

Once you’ve decided that your facility can benefit from power factor

correction, you’ll need to choose the optimum type, size, and the number

of capacitors for your plant.

There are two basic types of capacitor installations: individual

capacitors on linear or sinusoidal loads, and banks of fixed or

automatically switched capacitors at the feeder or substation.

Individual vs. banked installations

Advantages of individual capacitors at the load:

• Complete control; capacitors cannot cause problems

on the line during light load conditions

• No need for separate switching; motor always operates

with capacitor

• Improved motor performance due to more efficient power

use and reduced voltage drops

• Motors and capacitors can be easily relocated together

• Easier to select the right capacitor for the load

• Reduced line losses

• Increased system capacity

Advantages of bank installations at the feeder or substation:

• Lower cost per kVAR

• Total plant power factor improved—reduces or eliminates all

forms of kVAR charges

• Automatic switching ensures the exact amount of power factor

correction, eliminates over-capacitance and resulting overvoltage's

Consider the particular needs of your plant

When deciding which type of capacitor installation best meets your

needs, you’ll have to weigh the advantages and disadvantages of

each and consider several plant variables, including load type, load

size, load constancy, load capacity, motor starting methods, and

manner of utility billing.

Load type

If your plant has many large motors, 50 hp and above, it is usually

economical to install one capacitor per motor and switch the

capacitor and motor together. If your plant consists of many small

motors, 1/2 to 25 hp, you can group the motors and install one

capacitor at a central point in the distribution system. Often, the

best solution for plants with large and small motors is to use both

types of capacitor installations.

Load size

Facilities with large loads benefit from a combination of individual

load, group load, and banks of fixed and automatically-switched

capacitor units. A small facility, on the other hand, may require only

one capacitor on the control board.

Sometimes, only an isolated trouble spot requires power factor

correction. This may be the case if your plant has welding machines,

induction heaters, or DC drives. If a particular feeder serving a low

power factor load is corrected, it may raise overall plant power factor

enough that additional capacitors are unnecessary.

Load constancy

If your facility operates around the clock and has a constant load

demand, fixed capacitors offer the greatest economy. If the load is

determined by eight-hour shifts five days a week, you’ll want more

switched units to decrease capacitance during times of reduced load.

Load capacity

If your feeders or transformers are overloaded, or if you wish

to add additional load to already loaded lines, correction must be

applied at the load. If your facility has surplus amperage, you can

install capacitor banks at main feeders. If the load varies a great deal,

automatic switching is probably the answer.

Utility billing

The severity of the local electric utility tariff for power factor will affect

your payback and ROI. In many areas, an optimally designed power

factor correction system will pay for itself in less than two years.

How much kVAR do I need?

The unit for rating power factor capacitors is a kVAR, equal to

1000 volt-amperes of reactive power. The kVAR rating signifies how

much reactive power the capacitor will provide.

Sizing capacitors for individual motor loads

To size capacitors for individual motor loads, use Table 3 on the

following page. Simply look up the type of motor frame, RPM, and

horsepower. The charts indicate the kVAR rating you need to bring

power factor to 95%. The charts also indicate how much current is

reduced when capacitors are installed.

Sizing capacitors for entire plant loads

If you know the total kW consumption of your plant, its present

power factor, and the power factor you’re aiming for, you can use

Table 6 to select the capacitor

At the Load

Because capacitors act as kVAR generators, the most efficient place

to install them is directly at the motor, where kVAR is consumed.

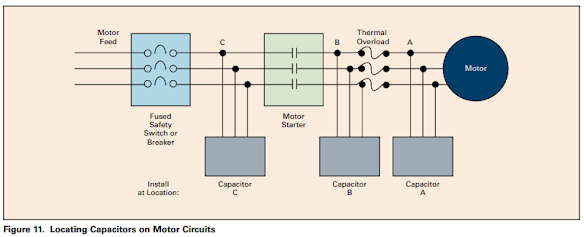

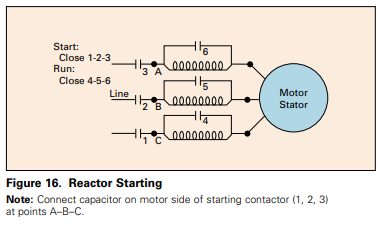

Three options exist for installing capacitors at the motor. Use

Figure 10 through Figure 16 and the information below to

determine which option is best for each motor.

Location A—motor side of overload relay

• New motor installations in which overloads can be sized

in accordance with the reduced current draw

• Existing motors when no overload change is required

Location B—line side of the starter

• Existing motors when overload rating surpasses code

Location Cline side of the starter

• Motors that are jogged, plugged, reversed

• Multi-speed motors

• Starters with open transition and starters that

disconnect/reconnect capacitor during cycle

• Motors that start frequently

• Motor loads with high inertia, where disconnecting the motor

with the capacitor can turn the motor into a self-excited generator

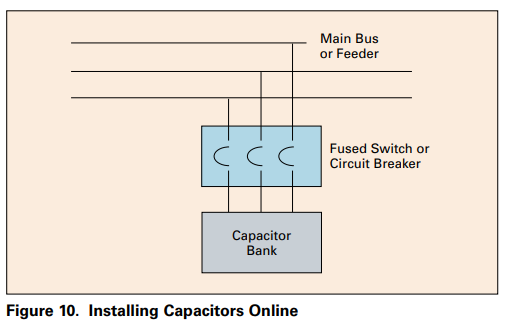

At the Service Feeder

When correcting entire plant loads, capacitor banks can be installed

at the service entrance, if load conditions and transformer size

permit. If the amount of correction is too large, some capacitors can

be installed at individual motors or branch circuits.

When capacitors are connected to the bus, feeder, motor control

center, or switchboard, a disconnect and overcurrent protection

must be provided.

Locating capacitors on reduced voltage and multi-speed motors

What about maintenance?

Capacitors have no moving parts to wear out and require very little

maintenance. Check fuses on a regular basis. If high voltages,

harmonics, switching surges, or vibration exists, fuses should be

checked more frequently.

Capacitors from Eaton operate warm to the touch. If the case is

cold, check for blown fuses, open switches, or other power losses.

Also check for bulging cases and puffed-up covers, which signal

operation of the capacitor interrupter.

source: Power Factor Correction by Eaton Technical Data SA02607001E

Thanks for this explicit explanation.

ReplyDeleteThanks for sharing this in-depth information on power factor correction and capacitor installation! It's really helpful to understand the importance of power factor correction and how it can benefit industrial facilities. Know more about the best electrical engineering colleges in coimbatore

ReplyDelete